In the construction industry, as the concept of green building has been deeply rooted in people’s hearts, more and more environmentally friendly building materials are widely used. Among them, PVC building formwork, as a high-performance, recyclable green building material, is gradually becoming the preferred choice in modern construction. This article will deeply explore the characteristics, advantages and applications of PVC building formwork in the field of construction, and reveal how it leads the green revolution in the construction industry.

1. Definition and characteristics of PVC building formwork

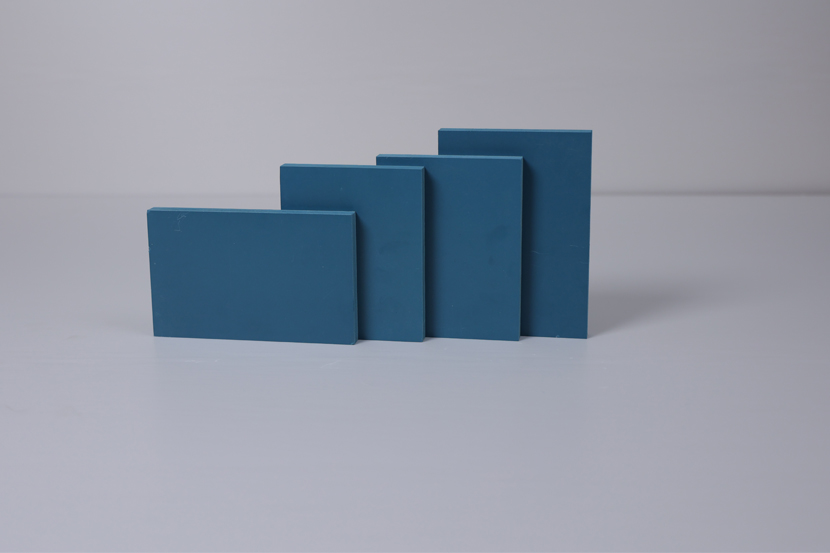

PVC building formwork, full name polyvinyl chloride building formwork, is a new type of building formwork made of polyvinyl chloride (PVC) as the main raw material and processed by special technology. PVC material itself has the characteristics of non-toxic, odorless, corrosion-resistant and strong weather resistance, which makes PVC building formwork perform well in construction. Its smooth surface and easy demoulding can ensure the quality of the concrete forming surface. At the same time, the lightweight characteristics of PVC material also greatly reduce the difficulty and cost of construction.

2. Advantages of PVC building formwork

Environmental protection and sustainability: PVC building formwork is made of recyclable materials, which can be recycled and reused after disposal, effectively reducing resource waste and environmental pollution. Compared with traditional wooden formwork, PVC building formwork has less impact on the environment during production and use, and is more in line with the requirements of green buildings.

High durability: PVC building formwork has high durability and weather resistance, and is not easy to be affected by moisture, deformation and damage. This allows the formwork to be used repeatedly many times, greatly reducing the generation and disposal costs of construction waste.

Lightweight and easy to install: The lightweight characteristics of PVC building formwork make it easier to carry and install, reduce the labor intensity of workers, and improve construction efficiency. At the same time, the lightweight characteristics also reduce the time and cost of building and dismantling the formwork.

Smooth surface: The surface of PVC building formwork is smooth and easy to demold, which can ensure the quality of the concrete forming surface. This is of great significance to improving the overall quality and aesthetics of the construction project.

3. Application of PVC building formwork

PVC building formwork has been widely used in construction due to its many advantages. Whether it is large-scale projects such as high-rise buildings, bridges, tunnels, or small-scale projects such as ditches, retaining walls, and pipe galleries, PVC building formwork can play its unique advantages. Especially in the construction of curved structures, the flexibility and easy deformation of PVC building formwork make it the preferred material for curved formwork.

As a high-performance, recyclable green building material, PVC building formwork is leading the green revolution in the construction industry with its unique advantages. In the future construction field, we look forward to seeing more environmentally friendly and sustainable building materials appear, and jointly contribute to building a green and healthy home on Earth. The widespread application of PVC building formwork not only reflects the responsibility and commitment of mankind to environmental protection, but also demonstrates the perfect combination of scientific and technological progress and sustainable development. Let us work together to welcome the bright future of green buildings.

Previous: PVC foam board: light weight, high strength, widely used building and decoration materials

Next: none

PVC partition board (wbt560)

1. Introduction PVC partition board, also known as foamed polyvinyl chloride board, has the characteristics of moisture resistance, heat preservation and corrosion resistance, light texture but high hardness, which is not easy to scratch and aging de...

PVC foam board

PVC foam board is also called Chevron board or Andy board, its chemical composition is polyvinyl chloride, so it is also called foamed polyvinyl chloride board. It is widely used in passenger cars, train car roofs, box core layers, interior decoratio...

PVC foam board (wbt010)

product description PVC foam board is also called Chevron board or Andy board, its chemical composition is polyvinyl chloride, so it is also called foamed polyvinyl chloride board. It is widely used in passenger cars, train car roofs, box core layers...

Wood veneer

It is mainly composed of two parts: substrate and surface film. The main component of the substrate is polymer material, the surface film is divided into PVC film and PP film, and the surface is covered with wood grain. When making it, the natural wo...